The requirement for clean equipment has long been part of FDA requirements since the 1963 GMP Regulations (Part 133.4) stating as follows “Equipment *** shall be maintained in a clean and orderly manner ***.” In the 1978 cGMP regulations, a very similar section on equipment cleaning (211.67) was included. FDA investigators have always looked for gross insanitation due to inadequate cleaning and maintenance of equipment and/or poor dust control systems. It continues to be a focus for inspectors. At the beginning of each federal fiscal year, the US FDA posts the previous year’s Form 483 observation metrics issued by each product center. The 2016 Fiscal Year top 5 observations reported by the Drug sector are:

- Procedures applicable to the quality control unit are not in writing and/or not fully followed

- Laboratory controls are not scientifically sound and appropriate

- Failure to thoroughly review unexplained discrepancies

- Lack of written procedures for production and process controls

- Written procedures are not followed for the cleaning/maintenance of equipment and utensils

Here are some specific examples from the past two years.

- The FDA issued a Form 483 to a New Jersey based facility over cleaning, sanitation and quality control issues after an October 2017 inspection.

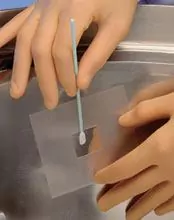

The investigator noted inadequate methods for cleaning and maintaining equipment. For example, a dirty rag was found inside the firm’s tablet press, and a yellow powder was found on equipment in the firm’s coating room, though the last product on the production line was white in color. Written procedures for cleaning and maintaining equipment and utensils used in the manufacturing of drug products were not followed, according to the report. Metal detectors were observed without cleaning procedures and safety instructions. In addition, devices were not fully covered in an equipment storage room, a stainless steel scoop did not have a bag, and there were no cleaning procedures for multiple items in the room. The agency also observed sanitation issues during the inspection. The investigator found a dead insect on the floor of the facility’s pharmacy room, and determined that complete cleaning was not possible because of rusted filing cabinets, packaging components and various materials throughout the room. 2. In February 23, 2016 a form 483 was issued to a drug manufacturing facility citing cleaning procedures as follows: Cleaning Procedures: There is no assurance that your cleaning and sanitization methods are adequate …………Cleaning and sanitizing procedures for kettles, vessels, and transfer pumps lack detailed instructions. This is particularly important for your product mix in that the insolubility of some excipients and active ingredients makes equipment difficult to clean, and could result in cross-contamination between your products. No cleaning procedures were established for the (b)(4) production equipment used to fill topical drug products *********.As mentioned in Charge 1, lot (b)(4) failed microbial testing. In your response to the FDA 483, you provided an updated Master Cleaning Validation Plan. You will use a matrix approach to update your procedures. However, you provided insufficient detail for us to determine the adequacy of your new plan, or the effectiveness of your plans for products already manufactured on inadequately cleaned equipment. In your response to this letter, please provide a detailed cleaning validation plan, including cleaning agent concentrations, hold times before cleaning, equipment disassembly instructions, cleaning frequencies, rinse times, and water temperatures; timeframes for completing your Master Cleaning Validation Plan; and a summary of your interim plan to ensure the quality of drugs that you continue to manufacture and distribute before you complete your corrective action and cleaning validation activities.” 3. Early in 2017, a Warning Letter was issued by the FDA citing Inadequate Cleaning Validation to an API manufacturing facility. Among the problems that FDA inspection noted were:

- Inadequate cleaning and contamination prevention measures.

- Failure to ensure compliance with cGMPs regarding material testing

- Insufficient quality requirements for batch release.

Manufacturing equipment was found to contain rust and insects, while some pieces were damaged, and drug residue was found on equipment surfaces, suggesting that product batches were contaminated with small levels of previous batches of other APIs. The company’s corrective and preventive action plans were inadequate, FDA inspectors said, because they did not outline cleaning procedures and equipment maintenance procedures in detail. FDA asked for assurance of cleanliness, as well as evidence of thorough cleaning validation tests, maintenance programs, and risk assessment of released batches. If you would like assistance with your cleaning validation process – please connect with us +353 1 846 47 42 or contactirl@pharmalex.com.